Information is the First Step This first case study in which we share details of our testing process for the track and trace technology, demonstrates the different measurable parameters tracked within a CSafe RKN container during the first project pilot shipment.

Introduction

The ability to track and view a shipment, in real-time, has been a topic of discussion within the cold chain industry for years. Pharmaceutical product stability is critical for drug effectiveness. As the logistics industry as a whole has been influenced by the digital innovations delivered by Amazon and others, it became clear that pharmaceutical shipment tracking was due for an upgrade.

CSafe Global researched, questioned, adjusted, calibrated, and ultimately selected a final tracking device provider and visibility platform developer to build a bestin-class air cargo tracking service for our customers. With the goal of spreading this service across our solution offering, we also ensured that both the tracking device and visibility platform are agnostic

and not reliant on the other.

Pilot Test Goals

Pilot Test A was designed to verify and validate the integration and operation of the Sendum PT300 hardware device within a CSafe active Air Cargo container on a live shipment.

The PT300 device was installed into multiple CSafe RKNs and CSafe RAPs, relying on the container battery to power the tracking device. The tracking device plus installed temperature probes record and transmit GPS location, ambient temperature and humidity, payload temperature, container tilt, container shock and container door opening and closing events.

Image 1 – CSafe RKN

The pilot shipment would be considered a success if container and payload readings and preset alerts, transmitted when appropriate, in real-time, during the transport.

Pilot Test Method

CSafe partnered with DHL Global Forwarding to complete the initial pilot shipment of CSafe RKN containers loaded with real cold chain product.

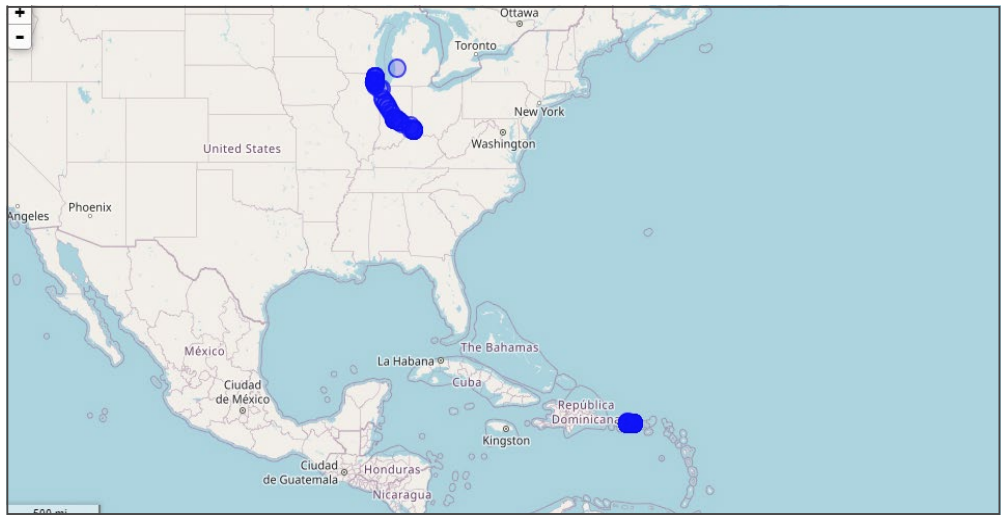

Table 1 – Pilot shipment transport details

Tracking software setup –All container tracking, alert and shipment configuration was setup in Sendum’s Findum platform, a standard feature for the software.

Geofence location creation– Geofence locations and alerts established at start and end warehouse facilities, DHL hub facilities in San Juan and Cincinnati, and at the SJU and CVG airports.

Hardware configuration – All tracking devices configured with alert limits based on profile and allowable parameters for the product inside each container.

GPS Location Tracking

Figure 1 – Real-time GPS location tracking of overall shipment.

Container was in flight-safe during flight which accounts for the break in data.

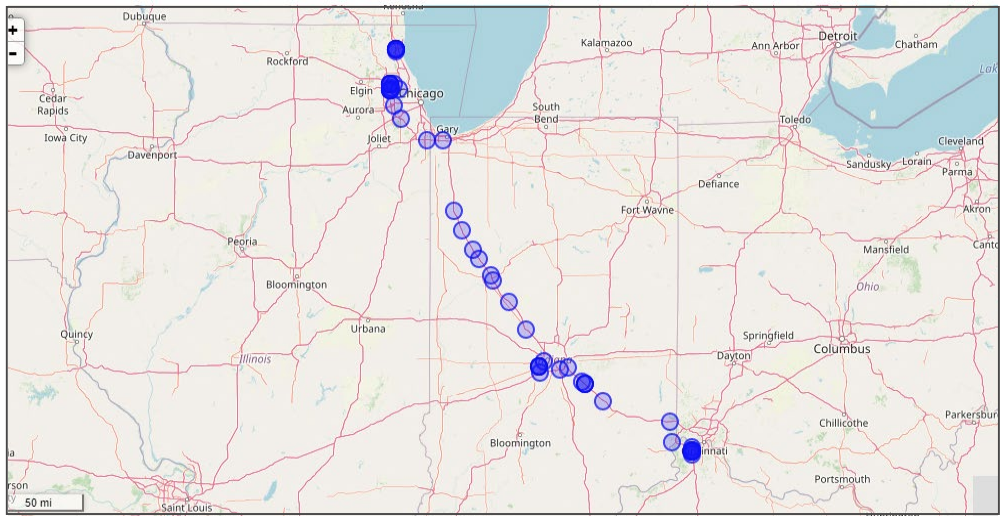

Figure 2 – Real-time GPS location tracking of the trucking leg of the shipment.

Results

Six Containers – RKN 01870, RKN 01821, RKN 01846, RKN 01427, RKN 00084, RKN 01571 were picked up from CSafe’s service center on June 2, 2020.

CSafe engineers tracked the containers to DHL’s SJU service center, the shipper’s manufacturing site (start location), the SJU airport and then went into flight-safe mode. When the containers landed at the CVG airport, engineers continued tracking during the truck transport to Chicago (end location).

All six containers completed their shipment and lease on June 4, 2020.

The figures shown in this section come from RKN 01870. Again, CSafe tracked a variety of readings including location, payload and ambient temperature, shock readings, cargo compartment pressure, payload humidity and container tilt. Additional elements available for measure include tilt, payload humidity and ambient air pressure.

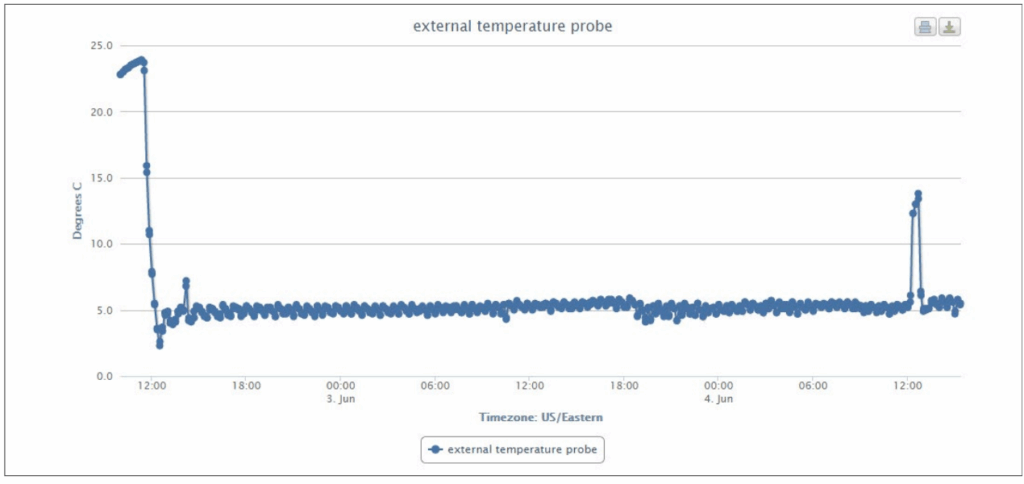

Payload Temperature

Figure 3 – Temperature readings inside the payload compartment during the shipment. The initial drop shows the conditioning

of the container and the two spikes in temperature match up with door opening events for the loading and unloading of product.

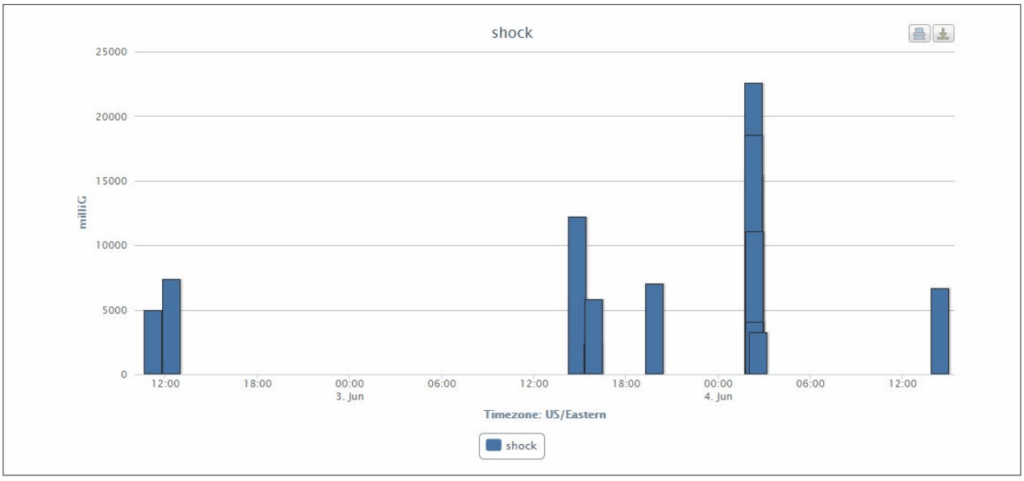

Shock Readings

Figure 4 – Shock data transmission throughout the shipment. Aligns with forklift movements, truck bumps and airplane landing.

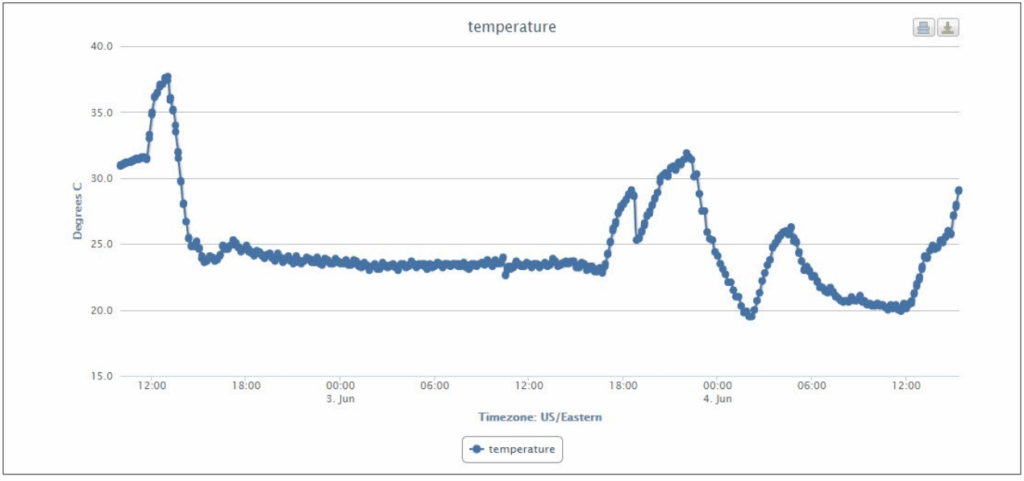

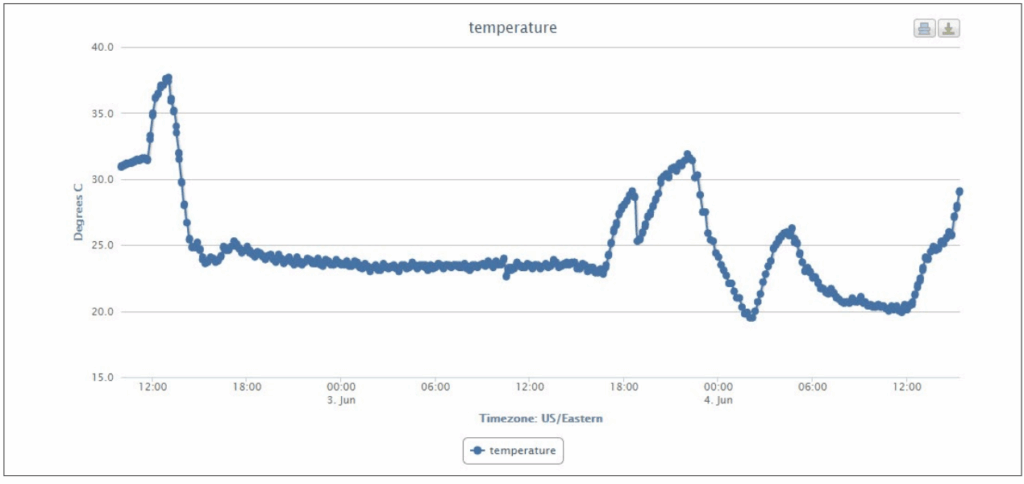

Ambient Temperature

Figure 5 – Ambient temperature readings recorded during shipment.

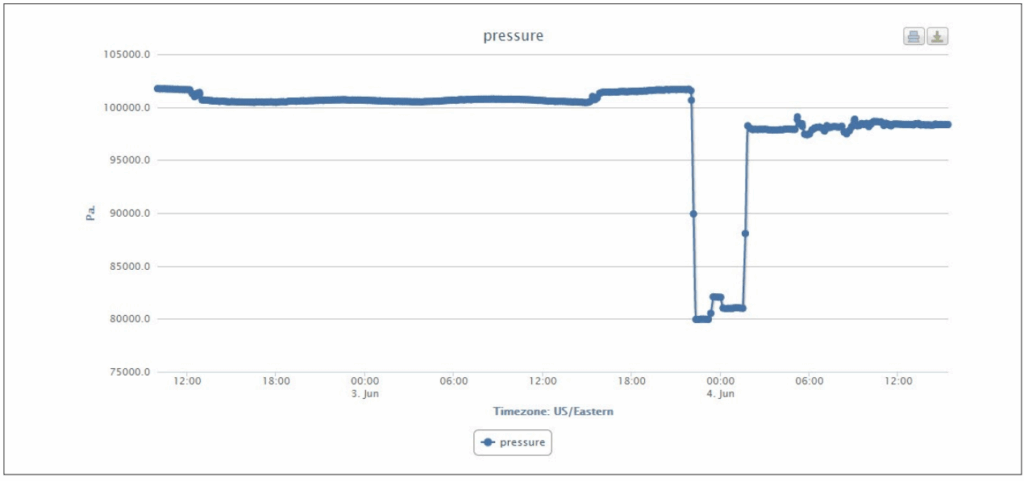

Cargo Compartment Pressure

Figure 6 – Pressure experienced inside the cargo compartment of the container. The pressure decreases when the doors are opened for container unloading.

Ambient Humidity

Figure 7 – Ambient humidity experienced during container shipment.

Summary

Six CSafe RKN containers successfully completed a DHL shipment from San Juan, Puerto Rico to Chicago, IL. All

tracking devices installed within the containers signaled appropriately and recorded data throughout the shipment. The Sendum PT300 works well within CSafe’s Air Cargo containers to measure, record and transmit data throughout the shipment. The next case study will confirm the accuracy of the Sendum PT300 data by comparing it to the shipment log files recorded directly from the container.

To learn more about how you can benefit from CSafe’s service offering, get in touch.

Your nearest sales representative is ready to help you maximize the impact of your life-saving therapeutics