Study confirms preventive maintenance program for CSafe RKNs is instrumental in preserving high-quality operational performance, regardless of container age.

Summary

Maintenance of mechanical systems is critical for consistent operational performance. This is understood across all industries ranging from automotive and aerospace to oil and chemical manufacturing. Cold chain transportation is no different, and CSafe understood this, and thus developed and deployed a robust Preventive Maintenance Rebuild (PMR) program before launching its CSafe RKN active container. This white paper is an updated version of an earlier study titled, “Maintenance of Active ULD’s and It’s Positive Impact on Performance and Longevity”.

The earlier paper examined the hypothesis that all CSafe active containers operate at a consistent and optimal performance level, regardless of age, as result of the PMR program. In the original study, a random sampling of containers that shipped together on a multi-container lease, performed almost identically.

To reconfirm the same hypothesis, this new study recruited the oldest container from the original study and compared it to a new random sampling of containers shipped together on another multi-container lease. Again, the data collected from the new selection of containers demonstrated virtually identical operational performance across each of the containers utilized.

Figure 1.

Mechanical systems require maintenance for consistent operational performance. This figure illustrates many of the mechanical systems found within a CSafe RKN that are regularly serviced through CSafe’s PMR program.

Background

As understood with any mechanical system (motor vehicles, airplanes, air conditioners, etc.), recurring maintenance is critical for optimal and consistent operational performance necessary to extend the service life of the system. CSafe’s engineering team incorporated this same philosophy into practice when they established a robust maintenance program to accompany the release of the very first CSafe RKN Active Temperature Controlled Container (ATCC) back in 2007. This Preventive Maintenance Rebuild (PMR) program developed and deployed by CSafe still operates today and consists of three core program elements: 1) Pre- and Post-shipment Inspection, 2) Annual Validation Testing and Scheduled Maintenance, and 3) Preventive Maintenance Rebuild. CSafe also established a best-in-class technical service team, available around-the-clock, to verify container performance and monitor service activities, for an added level of quality assurance.

PMR 1: Pre- and Post-shipment Inspection

Before and after every lease, CSafe’s network of service centers complete an in-depth system check on each of CSafe’s ATCCs. This detailed system check includes visual inspection and cleaning as necessary, functional testing, and refrigeration system testing – all to ensure overall container quality. Additionally, the technical service team reviews and analyzes the temperature data logs from each ATCC to assess for any potential anomalies prior to container release.

PMR 2: Annual Validation Testing and Scheduled Maintenance

Every year, CSafe completes system validation testing on every ATCC in their fleet. This includes battery testing, performance testing against the validated standard, temperature verification testing, and completion of scheduled maintenance checks. All containers must pass these stringent maintenance and validation tests before being released back into service.

PMR 3: Preventive Maintenance Rebuild

Every three years, CSafe ATCC’s are disassembled for visual inspection, functional testing of major system components, and replacement of batteries and any worn system components. Upon rebuild, each system installation is verified, temperature validation testing is completed, and a thorough final inspection is required before the container is returned back into service.

In 2016, CSafe conducted a container performance comparison study to test the hypothesis that CSafe’s PMR program is beneficial for the like-new operation of CSafe’s fleet of RKN active containers, regardless of container manufacture date. Upon study completion, it was determined that all seven of the CSafe RKNs under examination performed almost identically without a statistically significant difference in cargo compartment temperature data or battery life depletion.

To further demonstrate the importance of the PMR program, CSafe recently conducted a new investigation, with similar objectives as the initial study, to reconfirm the original hypothesis to be true – ie. that an established PMR program preserves the performance and quality of CSafe’s fleet of active containers, regardless of container age. To ensure that this secondary study is comparable to the original study, CSafe grouped a sampling of containers that included the oldest container from the original study, to be used on a multi-container shipment.

Methods

The objective of the new study was to conduct a similar container performance comparison test to that of the original study completed in 2016. The protocol required a random sampling of five containers, leased to carry the same product, at the same temperature, on the same shipment lane for the same customer. Controlling the shipment journey, customer, and payload set-point temperature was crucial for reducing the effects of any uncontrollable elements and variables on the results.

Container Selection –

The sampling of active containers selected for this study included CSafe RKN 00089, 00420, 00745, 01032, and 01487 with build dates ranging from early 2010 to a brandnew container built in January 2019. CSafe RKN 00089 was the oldest container used in the original study.

Data Tracking –

The temperatures inside and outside the CSafe RKNs were recorded by the Temperature Management System (TMS) integrated into each of the active containers. Temperature data was collected across an array of internal and external sensors

and charted to create a shipment profile showing both payload compartment temperature as well as ambient temperatures experienced by each container.

Shipment Profile –

The active container leases started in San Juan, Puerto Rico and ended at destination in Sydney, Australia with two stops in between and three flights to complete this overall shipment journey. The table and figure listed on the next page outline the stops along this route and the averaged ambient temperature the containers would experience during this time of year.

Table 1.

Table 1 outlines the

shipment details for this

multi-container lease.

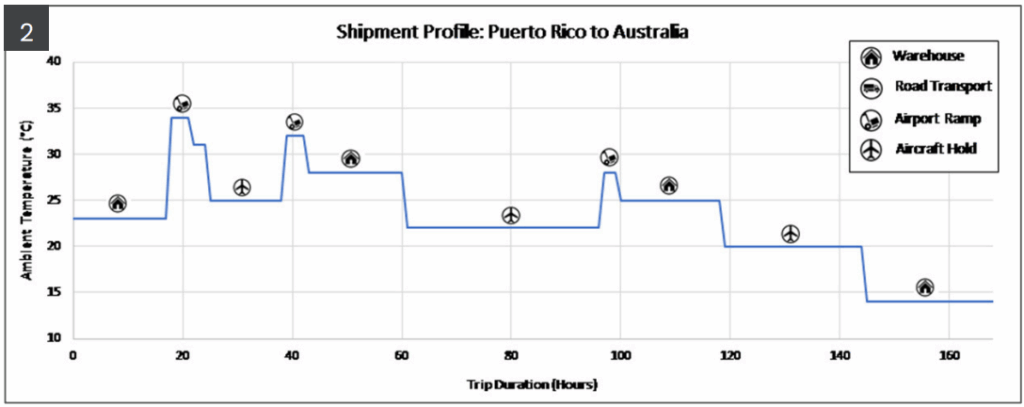

Figure 2.

Figure 2 illustrates the

theoretical, averaged

ambient shipment profile

these five containers may

experience this time of year.

Results

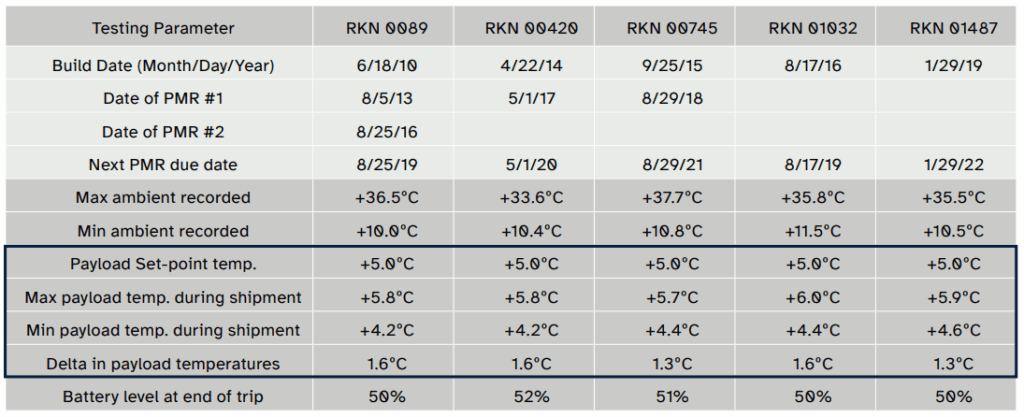

The data displayed in the table below demonstrates the consistency of the thermal mapping across all CSafe RKN containers, without any visible performance degradation relative to container age. The grey rows display the age of the container, how many scheduled Preventive Maintenance Rebuilds (PMR) have been performed to date, and when the next scheduled maintenance rebuild will occur. The green rows within the box outlined in blue show all information relative to the payload set-point temperature while the last row shows remaining battery life for each container upon completion of the overall shipment.

Table 2.

Table 2 summarizes data collected throughout

this program.

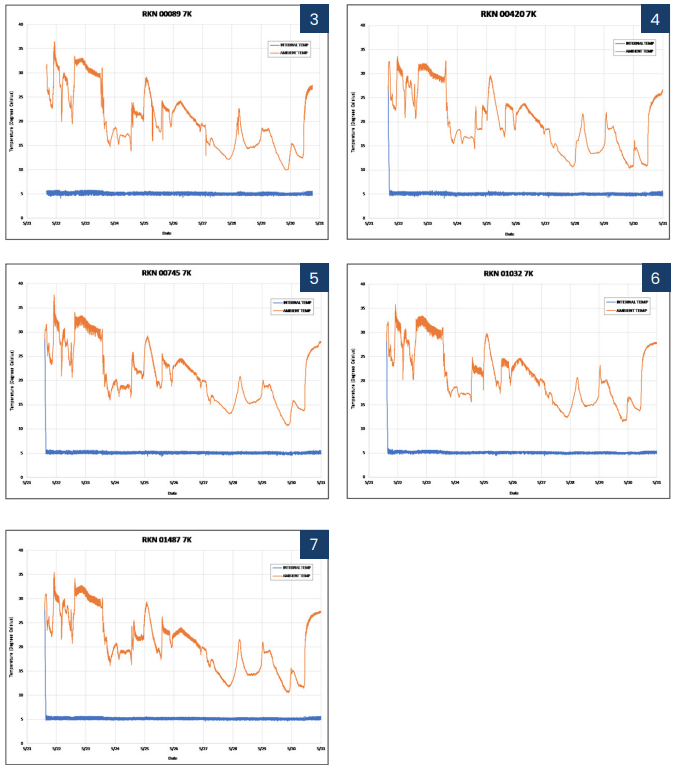

Figures 3 through 7.

These charts show the consistency of the cargo temperatures (navy blue) and the variability of the ambient temperatures (orange). Regardless of ambient challenges, all containers held tightly to the +5.0°C cargo temperature set-point.

The figures are shown in order of the container numbers listed in the

previous table: RKN 00089 (Fig. 3), RKN 00420 (Fig. 4), RKN 00745 (Fig. 5), RKN 01032 (Fig. 6), and RKN 01487 (Fig. 7).

Observations

The active containers utilized in this study maintained a tight temperature tolerance around the payload compartment set-point temperature while experiencing similar, warm ambient temperatures. The overall recorded delta in payload temperature for this shipment was 1.6°C based on the maximum (+6.0°C) and minimum (+4.4°C) recorded temperature in CSafe RKN 01032. This results in a precise tolerance band around the +5.0°C set-point temperature of only +1.0°C to -0.6°C for the 7-day shipment duration. All parties assisting with this shipment followed CSafe’s Standard Operating Procedures for battery charging and subsequently charged the containers each time they passed through a warehouse during transit. The study data demonstrated that container batteries had only depleted to roughly 86% before being recharged, prior to completion of the longest stretch on the batteries in the final leg of the transport. The concluding segment of the shipment lasted 4 days, and during this time the battery life had only been depleted by 50%, on average across all containers.

Conclusions

This study further demonstrates the effectiveness of CSafe’s industry-unique PMR program and confirms the program’s impact on the preservation of active container fleet performance. CSafe’s three-pronged approach to maintenance has been very effective and contributes to a positive user experience for CSafe’s customers with added peace of mind knowing that their high-value, life-enhancing products, are thermally protected when transported within a CSafe container. Having established a proactive PMR program with the support of a committed technical service team and a broad global Service Center Network, CSafe is able to sustain industry-leading quality and system performance of its fleet of ATCC’s, regardless of container serial number or date of manufacturing.

References

Neeld, Jonathan. “Maintenance of Active ULD’s and It’s Positive Impact on Performance and Longevity.” www.csafeglobal.com, CSafe Global, Oct. 2015, csafeglobal.com/ wp-content/uploads/2018/11/csafe-maintenance-of-rkn-final- 3pgweb-4-19-16.pdf.

To learn more about how you can benefit from CSafe’s service offering, get in touch.

Your nearest sales representative is ready to help you maximize the impact of your life-saving therapeutics.