In the pharmaceutical and temperature-sensitive logistics sectors, maintaining the integrity of products during transport is paramount. Thermal covers serve as critical barriers that protect cargo from temperature fluctuations and environmental elements. Understanding the performance capabilities of these solutions is crucial for achieving the compliance standards required to maintain the quality and integrity of medicines and other cargo throughout the supply chain.

This case study presents a performance analysis of two comparable thermal cover solutions: one from a notable, unnamed supplier, and the other, Silverskin QLT 19, from CSafe, which offers a comprehensive suite of thermal shipping solutions for the pharmaceutical cold chain.

The findings presented are based on third-party testing commissioned by a global pharmaceutical manufacturer looking to validate the performance of available solutions. CSafe was invited to participate based on its reputation for delivering product performance across a range of temperature control packaging (TCP) solutions for pharmaceutical cold chain shipping.

Test Methods

The study evaluated thermal performance by determining how effectively each thermal cover solution maintained the internal temperature of cargo during various stress tests. Third-party testing was conducted by a European-based transportation, logistics and warehousing company that ensured a controlled environment for all tests. The following protocols were adhered to:

Preparation

Testing was prepared utilizing new thermal covers, with a zero-mass product load that was constructed using empty cardboard boxes on standard European pallets (1200mm x 800mm) stacked to a height of approximately 1100mm.

Stabilization

All tested solutions were allowed to stabilize for ~18hrs in a Controlled Room Temperature (CRT) warehouse maintained between 15°C and 25°C.

Testing Scenarios

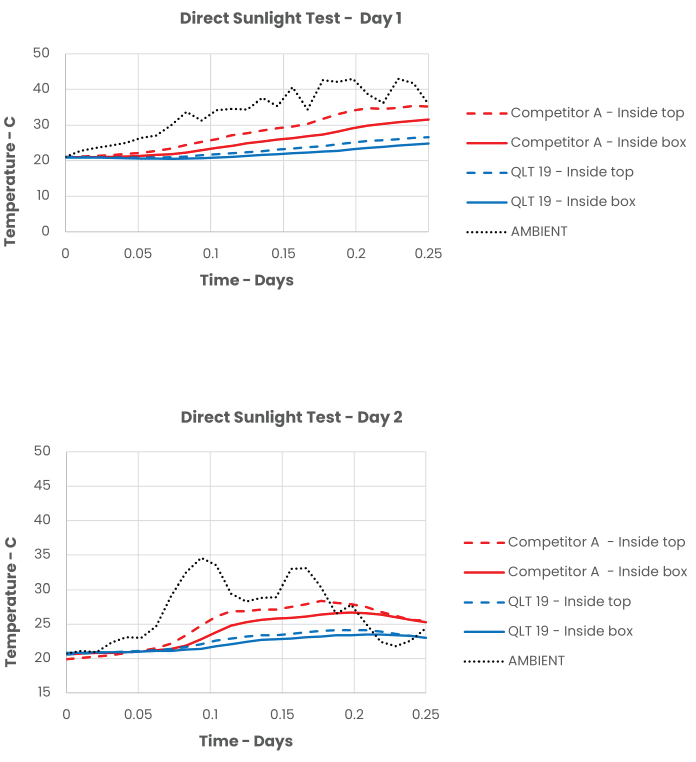

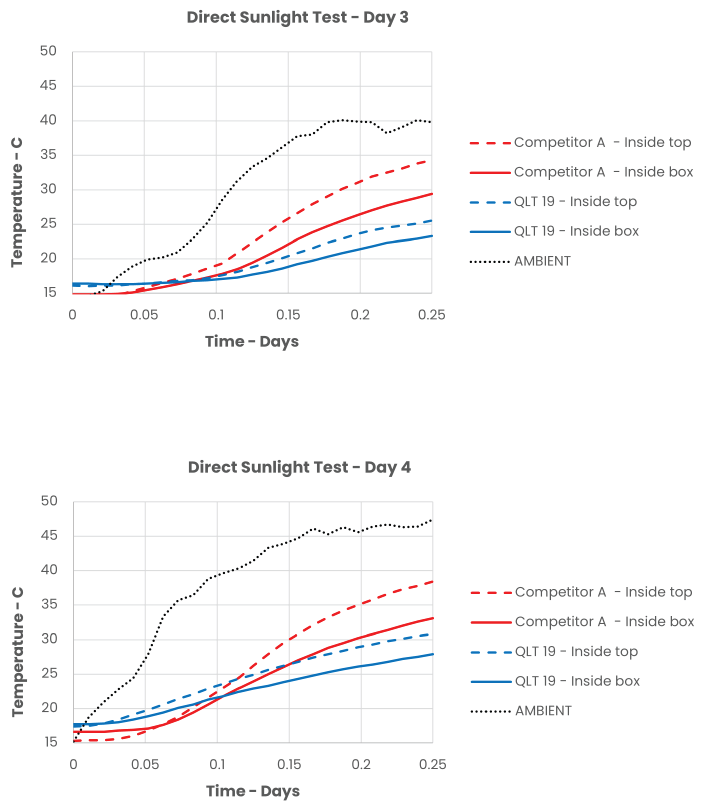

Following stabilization, three testing scenarios were applied. In the Direct Sunlight Test, the solutions were exposed to direct sunlight for 96 hours (4 days), with measurements recorded at 15 minute intervals. The Chilled Environment Test involved placing the solutions in a chilled storage facility at temperatures between 2°C and 8°C for 24 hours (1 day). This was followed by the third scenario, a return to CRT conditions for an additional 24 hours (1 day).

Measurement

Temperature readings were recorded from three locations: inside the payload box (‘Inside box’), outside the payload box under the protective cover (‘Inside top’) and ambient.

Results

Analysis

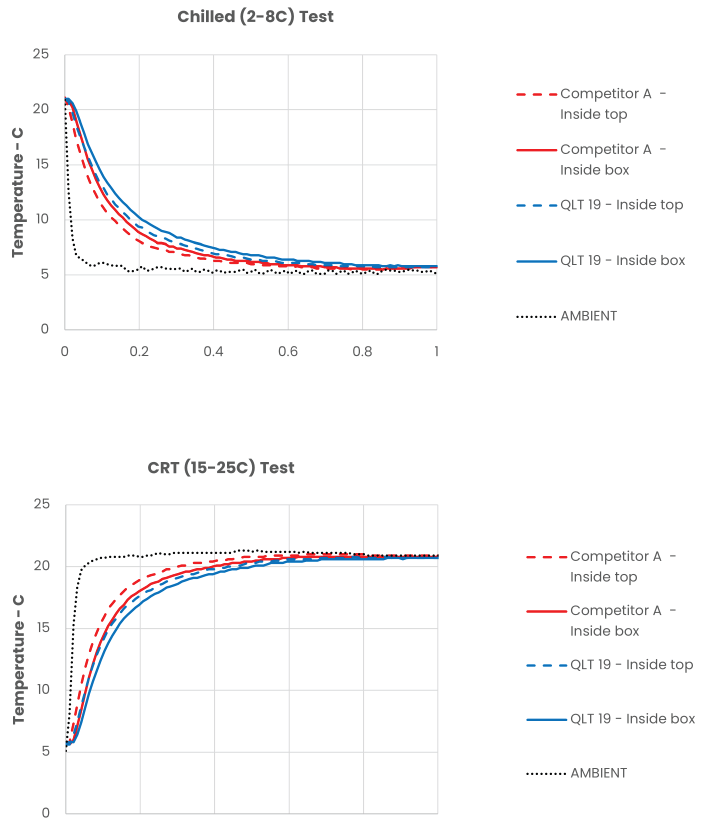

Using the data collected by the third-party testing organization, the effectiveness of each thermal cover was quantified with a Thermal Protection Factor (TPF). TPF is a measure that gauges how well a thermal cover solution maintains internal temperature under varying conditions.

The results highlight significant differences in performance between CSafe’s Silverskin QLT 19 and the other thermal cover.

- Most notably, Silverskin QLT 19 consistently outperformed the other thermal cover across all testing scenarios.

- During direct sunlight exposure, Silverskin QLT 19 covers achieved TPF values as high as 84.2%, compared with a maximum of 66.2% for the other tested solution.

Engineering for High Performance

It’s not surprising that Silverskin QLT 19 outperformed the other solution in its class of thermal covers.

It is among a wide range of “fit-for-purpose” solutions developed by CSafe that are engineered for high performance, ease of transport, assembly and environmental impact.

Operational Advantages

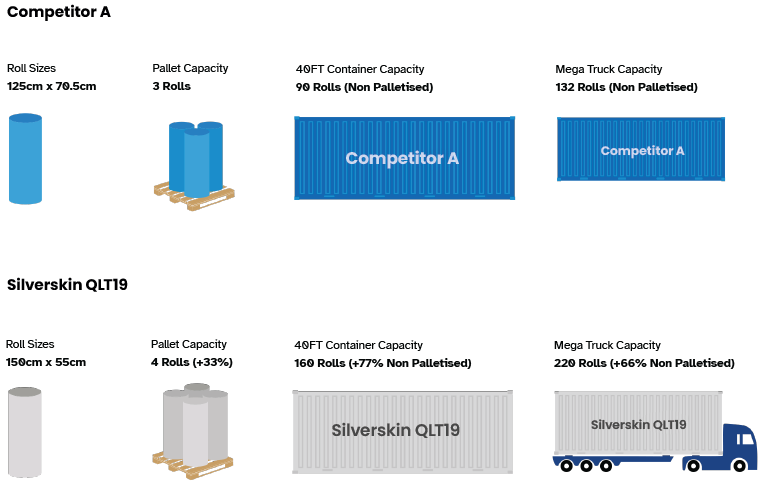

In addition to the thermal performance confirmed by the third-party testing, Silverskin QLT 19 is able to reduce environmental impact and operational costs. The design and compressibility of each thermal cover enables shipping and storage efficiencies, particularly in terms of container utilization and environmental impact.

A significant advantage of CSafe’s Silverskin QLT 19 is its ability to fit 30-40% more product within the same container compared with competing solutions. This efficiency leads to a reduction in storage needs and approximately 40% fewer freight vehicles required for transportation, resulting in lower carbon emissions and reduced transportation costs.

Conclusion

The comparative analysis of the two thermal cover solutions demonstrates Silverskin QLT 19’s clear superiority in thermal performance, with its ability to maintain temperature integrity during exposure to extreme conditions. Combined with its operational advantages, Silverskin QLT 19 delivers a level of performance that is crucial for pharmaceutical companies that prioritize product safety, regulatory compliance, and environmental sustainability in their supply chains.

The outcome of the third-party comparative testing provided the clear performance validation sought by the global pharmaceutical manufacturer that commissioned the assessment. As a result, the manufacturer has since switched to CSafe’s Silverskin QLT 19 as its preferred thermal cover solution.

To learn more about how you can benefit from CSafe’s service offering, get in touch.

Your nearest sales representative is ready to help you maximize the impact of your life-saving therapeutics