A CSafe whitepaper comparing water-based and PCM temperature control packaging systems.

Introduction to water-based and PCM coolants

This document provides guidance on the selection of water-based or PCM Pharmacool® coolants, and details the benefits of both types of Pharmacools based on CSafe qualification methodology.

Both water-based and PCM Pharmacool coolants achieve cooling by changing states or phases, most commonly from a solid to a liquid, a process which absorbs heat. Either type of Pharmacool can be used to maintain the two most common product temperature ranges: +2ºC to +8ºC and +15ºC to +25ºC.

Water-based coolants

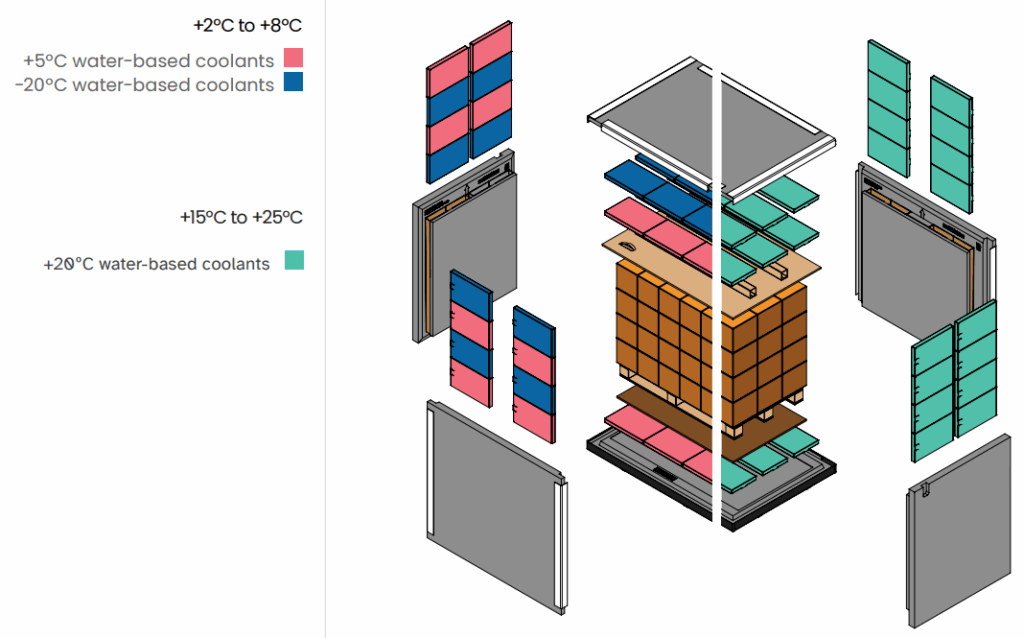

Water goes through phase change at 0ºC which is a few degrees colder than the ideal temperature for the shipping of temperature-sensitive goods with a temperature range of +2ºC to +8ºC.

To achieve the optimal temperature range, a thermal ‘gradient’ is created using a combination of Chilled (+5ºC) and Frozen (-20ºC) Pharmacools within a layer of internal insulation. This combination results in the desired +2ºC to +8ºC temperature range being maintained within the shipping system for a specific duration.

Ambient or CRT (Control Room Temperature) products tend to have a temperature range of +15ºC to +25ºC, so Pharmacools are conditioned at +20ºC without the need for phase change to occur.

PCM coolants

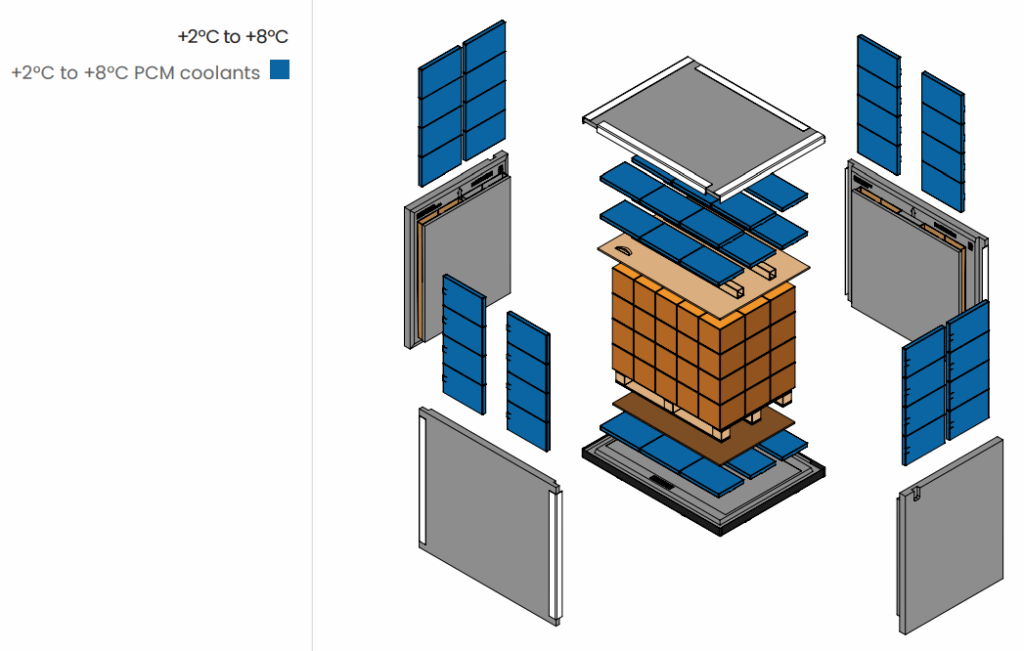

PCM means ‘Phase Change Material’ which is a term used to describe a range of different materials which provide very specific temperature control.

PCM coolants work on a similar principle to water-based coolants; however, as these have been designed to have a phase change or “melting” point at the desired product temperature (i.e. +5ºC for a chilled application) only a single type of coolant and conditioning process is required.. This simplifies the pack-out configuration and conditioning process.

PCM Pharmacools for ‘Ambient’ or CRT use cooling materials with a Phase Change point of +20ºC so are ideal for products with a temperature range of +15ºC to +25ºC.

Benefits of PCM coolants

Using Pharmacool PCM coolants has the following benefits over water-based coolants, particularly when shipping temperature sensitive products requiring strict +2ºC to +8ºC thermal performance:

- All-Year (Universal) Configuration with ONE Pharmacool type and temperature.

- Enable cold storage before and during shipping, without incurring temperature excursions for +2ºC to +8ºC shipments.

- Thermally robust ‘Pack, Ship & Forget’. Excursion reduction over waterbased systems used in uncontrolled lanes.

- Greater performance.

- Lower shipping weight. Improves operational efficiency by reducing complexity.

- No risk of cold shock. Seasonal pack-outs are not required.

Water-based or PCM?

The decision to select a shipping system with either water-based or PCM Pharmacools depends on a number of factors:

- Lane characteristics – Transit phase durations and temperatures

- Freight service – General cargo, IATA controlled or Cold Chain

- Shipping duration – Domestic 24 to 72 hours to long haul/international 72 to 120+ hours

- Desired Qualification profile – i.e. ISTA 7D, 7E, regional or lane specific

- Criticality – Patient / market need, shelf life and product value

- Complexity of packing operations – seasonal pack-outs, multiple product temperature ranges and/or shipper types

- Infrastructure – Conditioning capabilities (i.e. Ambient, Frozen and Chilled facilities)

- Short, Narrow or No product stability data

- Previous repeated temperature excursions on similar shipping lanes

CSafe can help you assess your situation and provide you with the most suitable shipping systems and optimal Pharmacool configurations based on your needs.

To learn more about how you can benefit from CSafe’s service offering, get in touch.

Your nearest sales representative is ready to help you maximize the impact of your life-saving therapeutics