Prolonged temperature excursion is the greatest enemy in the world of temperature controlled pharmaceutical shipping. Selecting the most appropriate cargo container and — more importantly — the insulation materials are critical factors in the success or failure of the mission. This is particularly critical for passive thermal shipping containers. Passive containers do not use batteries or active compressor/thermoelectric cooling. Instead, they rely only on the container design, insulation materials and any refrigerants used to maintain the required temperature needed for these high-value pharmaceutical products to remain effective from the point of origin to their final destination.

The ability to evaluate and select advanced insulation solutions will directly affect the available payload space inside the shipping container and the associated risk of temperature excursions that can lead to both spoilage and product losses. Additionally, your choice of insulation and refrigerants indirectly provide peace of mind for clinicians, pharmacists and patients by safeguarding medication viability.

VIP + PCM = The winning ticket

Vacuum Insulated Panels (VIP) — Maximizing thermal insulation with a slender profile.

Vacuum Insulated Panels (VIP) are highly-engineered panels that offer one of the most effective options for providing critical, long-term insulation inside of both active and passive shipping containers (Note: This article discusses only passive parcel containers. For information on active containers with VIP, see CSafe Air Cargo solutions).

These vacuum panels are constructed from a microporous core material (typically comprised of glass fibers, silica fibers, foams, mineral or glass wool, powders, fumed or pyrogenic silica, and silica aerogels) that is sandwiched between two pieces of multi-layer, laminate barrier film. This barrier film may be comprised of one or more materials, such as polypropylene, polyethylene, nylon, aluminum, polyethylene terephthalate, or combinations of them.

Compared with widely used alternative options for insulating the thermal shipping containers, VIP can provide R-values that are 10+ times higher than conventional materials. And thanks to their slender profile, a 1-inch-thick VIP panel helps to maximize the available internal payload space compared to more bulky insulation options. The ability to maximize the payload volume per footprint of each container helps optimize each shipment and reduce overall freight costs.

Phase change materials (PCM) — Advanced refrigerants provide additional temperature control.

The goal of any cold-chain shipping effort is to maintain the required storage temperature and avoid any fluctuations that could lead to damage. With ambient temperatures varying widely from one country to another at any time of the year, all efforts must be made to ensure that the internal payload is protected from these external temperature changes while in transit. Another consideration in addition to weather extremes or traveling from one climate to another is the possibility of extended time spent on the truck or tarmac during extreme weather.

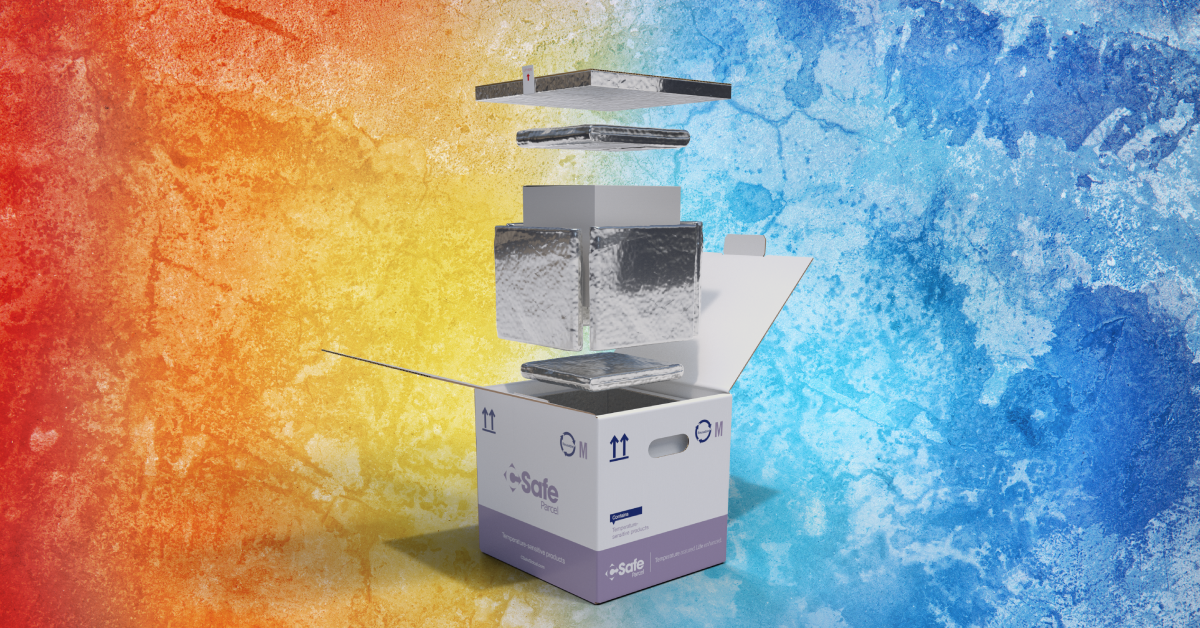

As noted, the high-efficiency, slim-profile VIP provides the required insulation while maximizing the available payload space inside the container. The space between the product itself and the VIP panels is then available to accommodate inserts that that use specialty phase-change material (PCM) to help maintain the temperature setpoint inside the container.

PCM is engineered material that can effectively store and release energy, and undergo a change in phase (for instance, solid-solid, solid-liquid, liquid-gas or solid-gas) as it is warmed or cooled. During the phase change, the PCM will absorb or release a known amount of heat per unit mass — while still maintaining a constant setpoint temperature — for a known duration of time, until the full volume of PCM has reached its new phase. Proven PCMs include hydrated salts, paraffins, fatty acids, alcohols and more. Each material has its own performance profile, so the most appropriate PCM can be closely matched to the specific temperature requirements of each shipment.

When standalone PCM panels are properly conditioned to the desired setpoint temperature and then placed tightly between the product packaging and top of the line VIP in the passive shipping container, the combination will reliably keep the pharmaceutical products at their storage temperature (refrigerated or frozen) and reduce the chance of temperature excursions during the journey.

By comparison, when passive containers rely on widely used water-based gel packs to provide a source of chilling inside the shipping container, a layered combination is often used (alternating both refrigerated and frozen gel packs) — as a precaution against temperature fluctuations over time. However, this approach adds extra weight to the package, reduces the available payload volume that is available for actual product inside the container, and increases the risk of both temperature stratification inside the package and temperature fluctuations over time during transit.

Using this advanced configuration of PCM panels and VIP to achieve improved temperature control inside the shipping container helps users avoid the need for seasonal pack-out configurations (to account for seasonal temperature extremes), which can help to reduce costs and risk and streamline pack and ship operations.

Closing thoughts

The cost of insulation can vary greatly when it comes to temperature-controlled shipping options, with traditional low R-value materials at the lower end of the spectrum and state-of-the-art VIP products on the higher end. The same is true for refrigerants, with water-based gel packs at the low end and PCM refrigerants at the higher end. What is important to factor into your cost analysis is the risk of temperature excursion. Beyond the lost product and the financial implications of that which are substantial, the risk includes customer relationships, public trust and most importantly – patients’ lives.

The combination of high-performance VIP and PCM panels that provide more precise temperature management inside the cargo container for hours or days, ensures safe and reliable transportation across the globe. This configuration can provide extended hold times of up to 240 hours. And when the container, insulation and refrigerants are also part of a retest and reuse program, the demonstrable return on investment comes quicker, helping these state-of-the-art thermal shipping options to pay for themselves in even less time.