Emilio Frattaruolo, CPP, Vice President of Innovation, Passive Systems discusses how to build flexibility into the cell and gene therapy supply chain.

We’ve covered compliance and risk mitigation relevant to this topic so what’s left? Flexibility. This is often one of the most difficult elements for businesses to embrace in the supply chain and absolutely critical to success.

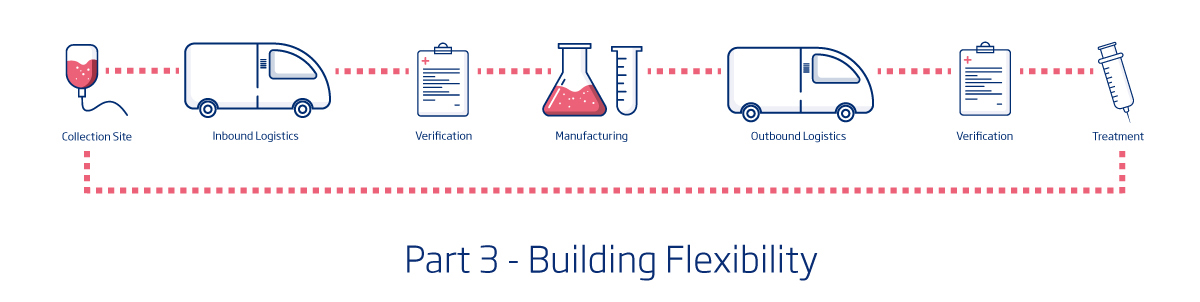

You might be shaking your head and saying, “Cell and gene therapies are exact. ‘Flexing’ is not a reality.” While that is certainly true in the therapy itself, it’s not when it comes to the supply chain. No one expects the cell and gene manufacturing process to flex. It must remain precise to be effective. However, looking at the basic supply chain, where is it possible to build in additional flexibility?

Let’s start with processes. Right now, because many cell and gene therapies are still in the clinical trial stage and not being widely used, demand is low. It will likely never be on the same scale as treatments for arthritis and diabetes but once treatments are approved, you’ll likely see a steep rise then fall in demand depending on the prevalence of the disease in question. Do you have processes in place to address changes in demand? Do your suppliers? Consistent processes at every stage of the supply chain eliminate confusion for everyone involved and allow for quick adjustments should they become necessary.

Next up: suppliers. Do have alternate suppliers vetted and qualified to jump in should a primary provider have issues? How well are your suppliers integrated into your business? Do you have frequent, strategic communication with your suppliers that involves forecasting? Do you work collaboratively with your suppliers on product development – both yours and theirs? You need to be doing all of these things if you aren’t already. Given the current crisis at hand, this should be more apparent than ever. Delivery services can unexpectedly become overwhelmed. Cargo space can become scarce. This not only affects you directly, but your suppliers as well. Having a network of suppliers and regular communication helps you better understand how you can flex and how they can help you to do it.

The last thing on my list is technology and data and how available it is to those involved in your supply chain. Below are a few questions to consider:

- What internal data is available to you that will help you and your suppliers plan and adjust? Are you sharing that with your suppliers?

- What data do you receive from your suppliers before, during and after transport? How quickly and easily can you obtain it?

- Using all internal and supplier data, how quickly are you able to analyze the combined information and provide it to leaders to determine if adjustments are needed?

When it comes to supply chain, it has become abundantly clear in the last four months that more data transparency is necessary in order to manage both extreme and more common disruptions in the cold chain. When you have access to data that helps you understand the severity of a disruption in transport and potential adverse effects to your shipment, you are equipped to make the best decision to protect your payload. If you don’t believe you have all that data, you need to engage your internal analytics teams and your critical suppliers to provide it to ensure you have the flexibility to make optimal decisions.

I hope you’ve found this series helpful as we all work through the challenges of a severely constrained worldwide supply chain. If you haven’t made this a focus prior to COVID-19, I’m certain it has become a focus in the last few months. If you missed Parts 1 & 2 of the series Managing Compliance and Risk Mitigation, there are some excellent resources in those to help you on your journey. And, of course, CSafe is happy to offer assistance to all of our customers with this effort.