Emilio Frattaruolo, CPP, Vice President of Innovation, Passive Systems discusses how to mitigate risk in the cell and gene therapy supply chain.

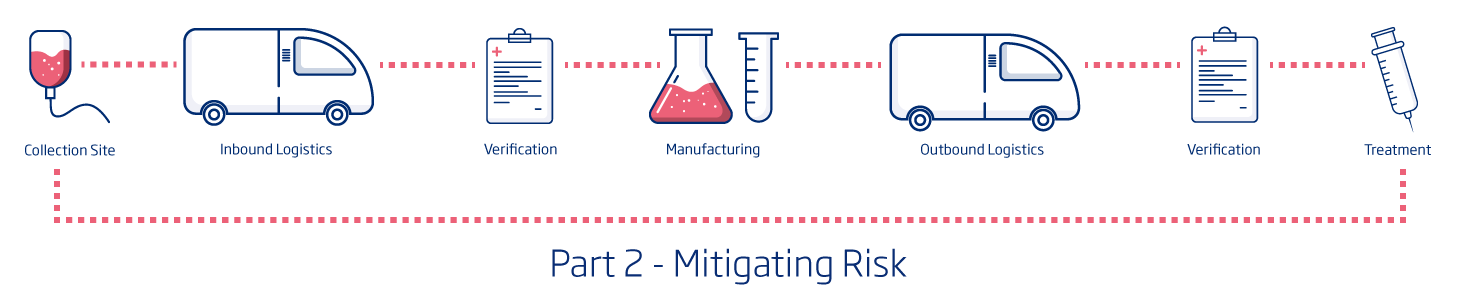

In part 1 of this series, I discussed managing compliance in each phase of your cell & gene supply chain to help ensure resiliency. Once this is done, you need to identify and mitigate all other potential risks to your supply chain. It sounds daunting, but it absolutely can be done.

For our purposes here, we’ll focus on the portions of the supply chain outside of medical facilities and cell & gene therapy manufacturing. First define a complete list of requirements for a successful transport process. This is your “perfect world” scenario. You must document everything from receiving the proper packaging and instructions to an ideal transit time, etc.

Then you have to start poking holes in your perfect world until it resembles your worst-case scenario. I recommend conducting an FMEA or Failure Modes and Effects Analysis to fully assess all of the risks associated with the transport process. You can use this to determine what improvements or precautions are necessary to ensure delivery. This involves working closely with your packaging and transport providers during testing and qualification to mimic the exact conditions in transit to identify all potential risks or possible points of failure.

Step three is mostly on your partners. What can they do to mitigate each risk factor? Some will be simple, like providing packing instructions in multiple languages. Others will be more complex. For instance, you’ll need mitigation strategies for:

- Severe weather and the aftermath at the level Puerto Rico has seen after Hurricane Maria and this year’s series of earthquakes

- A virus outbreak that results in local quarantines and global supply chain delays such as COVID-19

- Political issues like Brexit that directly influence regulatory standards and compliance

The list goes on. And while some of these may have once seemed far-fetched, we all now know these risks are real and they all directly affect the two worst case scenarios in the cold chain: temperature changes and time delays. Since we can’t control time or weather, what can manufacturers do to protect cell & gene payloads from these two issues?

- Insulation – Packaging insulation should be appropriate for your payload and colder isn’t always better so make sure you secure the right thermal shipping option with the highest quality insulation to protect your product.

- Hold time – Whether you need refrigerated or frozen temperature control, make sure the solution can accommodate your standard shipping time PLUS any unplanned delays. Again, testing that mimics real-world conditions and performs to the ISTA 7D standard is critical to protecting your cargo, so you need to subject every potential supplier to the same level of testing.

- Temperature monitoring – Access to real-time temperature monitoring can give you the data you need to intervene and safeguard the payload during transport should there be an issue.

Obviously, this is far from an exhaustive list of risks and mitigations. Each product will have its own distinct risk factors and steps that you, your packaging and transportation providers can take to insulate your supply chain from exposure. The most important part of this process is the thorough planning and cooperation between all parties before you pack your first box.