Cell & Gene Therapy Logistics Planning and Scaleup

The vibrant and growing pipeline of cell and gene therapies (CGT) provides many exciting clinical opportunities for patients and their physicians, and many financial opportunities for today’s innovative pharmaceutical companies. Whether the treatment uses autologous or allogenic production, all cell and gene therapies have complex requirements when it comes to the specialty packaging and chain-of-custody transport of both biological material used in manufacturing and the resulting therapy used to treat the patient.

Early involvement with approved CGT treatments has allowed the cold chain industry to develop a successful shipping and logistics methodology, and best practices are beginning to emerge thanks to a growing body of collective experience. However, most of today’s winning strategies related to temperature-controlled packaging, shipping and logistics management have been proven on a very small scale — often related to the management of just one patient’s biological materials or CGT product in a single highly coordinated delivery routine.

As successful CGT providers ramp from clinical development through commercial launch to large-scale market uptake, the cold-chain shipping needs will grow – perhaps from just a few shipments per week to hundreds or even thousands of shipments per week. The question on every pharma producer’s mind should be: “Can the existing delivery infrastructure scale over time, and can our current cold chain partners grow with us in terms of growing volume and global reach?”

Organic growth of the cold chain is not sufficient

As this vibrant section of the healthcare arena continues to grow, and the CGT pipeline continues to mature, all stakeholders in the space need to be thinking about and planning for scaleup, as early as possible in the product’s commercial lifecycle. Rather than just letting organic growth happen — and then potentially getting caught off guard by gaps in the cold chain packaging and shipping infrastructure — pharma companies should conduct their due diligence at the earliest opportunity to select cold chain packaging and logistics/freight forwarder partners that have the expertise, experience and global footprint to grow with the brand and handle future volume expansion seamlessly.

Due diligence considerations

As pharma companies work to evaluate potential partners to support the commercial success of their CGT offerings and identify best-in-class providers, they should consider these critical questions:

- Does the company have the resources, experience and partnerships needed to move high-value, time- and temperature-sensitive raw materials and finished CGT products across the globe?

- Is the company appropriately resourced to meet growing volume demand?

- Does the company have a global footprint including staff and service centers that can provide rapid response and troubleshooting for the temperature-controlled shipping containers?

- Does the company have an established network of local partners all over the world to help manage “the last mile” of the journey and avoid delays that could threaten the integrity of the product?

- Is the shipping container supplier able to provide all forms of temperature-controlled packaging (active and passive, long- and short-duration, small/hand-carry parcels and bulk containers) to meet the pharma company’s evolving needs?

- Does the container provider offer GPS tracking by container as well as monitoring for other key metrics such as temperature inside and outside the package? Does the company provide access 24/7 access to the monitoring platform to enable all stakeholders to assess the status and respond quickly, should issues or delays arise?

- Can the provider(s) easily conduct pilot-scale operations to evaluate various packaging and delivery configurations?

It’s never too early to plan for market expansion

Within the CGT space, a considerable amount of time and effort is spent on the early clinical development, regulatory approval and early product-launch phases. But there is so much more than just getting the product out the door. Today, most pharma companies are not spending enough time and effort early in the launch process to both envision and enable larger-scale commercial operations, especially regarding the need to reliably manage cold chain packaging and transportation requirements. Failure to identify suppliers and logistics partners that offer best-in-class capabilities — from the product or service offering to training programs, customer-service, continuous process improvement, and overall data-management practices that ensure quality and reliability of every shipment — signals a missed opportunity. The goal is to create a comprehensive and well-designed cold chain packaging, transportation and delivery infrastructure that will grow with your product. A strategic approach will bring tactical efficiencies, overall economies of scale and increased reliability that are not always possible when an infrastructure is created from a patchwork of options added over time.

The ability of any pharma company to establish strong, collaborative partnerships with proven cold chain packaging and logistics providers is essential to safeguarding critical CGT payloads through every step of the supply chain, while increasing volume and expanding geographically. The ability to establish a network of proven packaging suppliers and freight-forwarding partners ensures reliable chain-of-custody management of these critical packages — every time.

Reducing temperature excursions in cold chain shipping — The business imperative for using phase-change materials (PCM)

Prolonged temperature excursion is the greatest enemy in the world of temperature controlled pharmaceutical shipping. Selecting the most appropriate cargo container and — more importantly — the insulation materials are critical factors in the success or failure of the mission. This is particularly critical for passive thermal shipping containers. Passive containers do not use batteries or active compressor/thermoelectric cooling. Instead, they rely only on the container design, insulation materials and any refrigerants used to maintain the required temperature needed for these high-value pharmaceutical products to remain effective from the point of origin to their final destination.

The ability to evaluate and select advanced insulation solutions will directly affect the available payload space inside the shipping container and the associated risk of temperature excursions that can lead to both spoilage and product losses. Additionally, your choice of insulation and refrigerants indirectly provide peace of mind for clinicians, pharmacists and patients by safeguarding medication viability.

VIP + PCM = The winning ticket

Vacuum Insulated Panels (VIP) — Maximizing thermal insulation with a slender profile.

Vacuum Insulated Panels (VIP) are highly-engineered panels that offer one of the most effective options for providing critical, long-term insulation inside of both active and passive shipping containers (Note: This article discusses only passive parcel containers. For information on active containers with VIP, see CSafe Air Cargo solutions).

These vacuum panels are constructed from a microporous core material (typically comprised of glass fibers, silica fibers, foams, mineral or glass wool, powders, fumed or pyrogenic silica, and silica aerogels) that is sandwiched between two pieces of multi-layer, laminate barrier film. This barrier film may be comprised of one or more materials, such as polypropylene, polyethylene, nylon, aluminum, polyethylene terephthalate, or combinations of them.

Compared with widely used alternative options for insulating the thermal shipping containers, VIP can provide R-values that are 10+ times higher than conventional materials. And thanks to their slender profile, a 1-inch-thick VIP panel helps to maximize the available internal payload space compared to more bulky insulation options. The ability to maximize the payload volume per footprint of each container helps optimize each shipment and reduce overall freight costs.

Phase change materials (PCM) — Advanced refrigerants provide additional temperature control.

The goal of any cold-chain shipping effort is to maintain the required storage temperature and avoid any fluctuations that could lead to damage. With ambient temperatures varying widely from one country to another at any time of the year, all efforts must be made to ensure that the internal payload is protected from these external temperature changes while in transit. Another consideration in addition to weather extremes or traveling from one climate to another is the possibility of extended time spent on the truck or tarmac during extreme weather.

As noted, the high-efficiency, slim-profile VIP provides the required insulation while maximizing the available payload space inside the container. The space between the product itself and the VIP panels is then available to accommodate inserts that that use specialty phase-change material (PCM) to help maintain the temperature setpoint inside the container.

PCM is engineered material that can effectively store and release energy, and undergo a change in phase (for instance, solid-solid, solid-liquid, liquid-gas or solid-gas) as it is warmed or cooled. During the phase change, the PCM will absorb or release a known amount of heat per unit mass — while still maintaining a constant setpoint temperature — for a known duration of time, until the full volume of PCM has reached its new phase. Proven PCMs include hydrated salts, paraffins, fatty acids, alcohols and more. Each material has its own performance profile, so the most appropriate PCM can be closely matched to the specific temperature requirements of each shipment.

When standalone PCM panels are properly conditioned to the desired setpoint temperature and then placed tightly between the product packaging and top of the line VIP in the passive shipping container, the combination will reliably keep the pharmaceutical products at their storage temperature (refrigerated or frozen) and reduce the chance of temperature excursions during the journey.

By comparison, when passive containers rely on widely used water-based gel packs to provide a source of chilling inside the shipping container, a layered combination is often used (alternating both refrigerated and frozen gel packs) — as a precaution against temperature fluctuations over time. However, this approach adds extra weight to the package, reduces the available payload volume that is available for actual product inside the container, and increases the risk of both temperature stratification inside the package and temperature fluctuations over time during transit.

Using this advanced configuration of PCM panels and VIP to achieve improved temperature control inside the shipping container helps users avoid the need for seasonal pack-out configurations (to account for seasonal temperature extremes), which can help to reduce costs and risk and streamline pack and ship operations.

Closing thoughts

The cost of insulation can vary greatly when it comes to temperature-controlled shipping options, with traditional low R-value materials at the lower end of the spectrum and state-of-the-art VIP products on the higher end. The same is true for refrigerants, with water-based gel packs at the low end and PCM refrigerants at the higher end. What is important to factor into your cost analysis is the risk of temperature excursion. Beyond the lost product and the financial implications of that which are substantial, the risk includes customer relationships, public trust and most importantly – patients’ lives.

The combination of high-performance VIP and PCM panels that provide more precise temperature management inside the cargo container for hours or days, ensures safe and reliable transportation across the globe. This configuration can provide extended hold times of up to 240 hours. And when the container, insulation and refrigerants are also part of a retest and reuse program, the demonstrable return on investment comes quicker, helping these state-of-the-art thermal shipping options to pay for themselves in even less time.

Cell & Gene Therapy Commercialization Logistics: 3 Critical Questions to Ask when Choosing a Thermal Shipping Container

Among today’s temperature-sensitive pharmaceutical products requiring specialized handling, transport and storage, cell and gene therapies (CGT) need even more precise logistical planning than many others. A given CGT product is typically produced in single individualized doses or in small batches to treat a debilitating or life-threatening genetic disease. Because CGT therapies are highly individualized, each supply chain is unique and each selecting partners and providers is critical.

CGT producers must work closely with shipping partners and thermally protective packaging (TPP) providers. Ideally, you want to partner with an experienced, global supplier that won’t just hand you a temperature-controlled container and walk away. A preferred thermal packaging provider offers guidance by conducting a gap analysis to identify and prioritize your tactical and strategic needs and also can scale as your process moves from clinical development through regulatory approval to commercial operations. Similarly, your supplier should be able to perform physical testing and thermal modeling, provide documentation to meet GDP requirements, and offer advisory support to prepare for regulatory approval and potential audits down the line.

It’s also never too early to begin your container selection process. When CGT producers and supply chain partners have time to fully vet and standardize the shipping process – including packing and handling the containers – they can reliably and cost-effectively safeguard these high-value products. Early container selection is especially important when a product requires customizations to the packaging design or its monitoring capabilities.

As you evaluate available thermal shipping containers for your CGT products, consider these questions.

#1 What does the overall supply chain look like for a given CGT product?

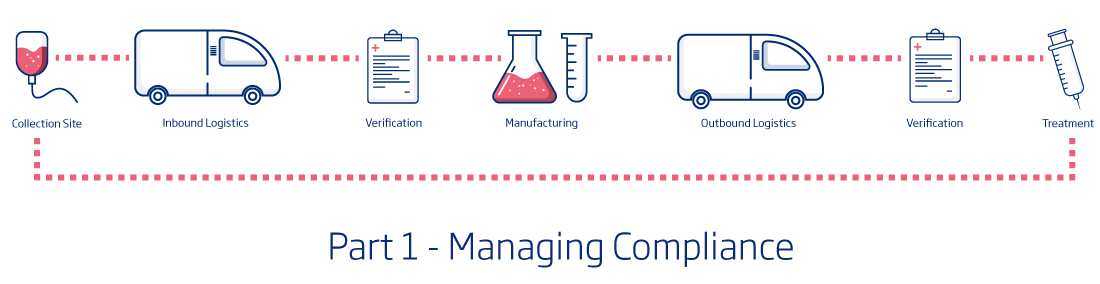

As mentioned, each supply chain is unique based on the individual CGT product, but in general the steps are:

- Clinician extracts biological materials from the patient.

- Raw materials transported to the CGT manufacturing site.

- CGT product is manufactured.

- Therapy delivered to clinical setting.

- Clinician infuses treatment into the patient.

There are special considerations for autologous vs. allogeneic therapies.

Autologous therapies use one patient’s whole blood, blood products, marrow or other tissue. The CGT manufacturer uses that as biological starting material and modifies it to produce a customized therapy. Once the individualized CGT product has been produced, it is transported back to the clinical setting to be infused into the initial donor patient in a closed-loop scenario that requires tightly coordinated handoffs.

Allogeneic therapies use blood or tissue from one donor patient to produce multiple doses of the CGT product which will ultimately be used to treat the donor patient and compatible patients who have been deemed eligible to receive it. Allogeneic therapies are produced in larger quantities (compared to the single-dose manufacturing process used for autologous therapies). Individual doses of the finished therapy are distributed to multiple sites to be infused into multiple patients — each requiring its own temperature-controlled delivery process.

Whether it’s an autologous or allogeneic product, the CGT supply chain requires unprecedented levels of coordination for scheduling each shipment and maintaining a constant temperature.

#2 What durations do you expect to encounter for your shipment, in terms of storage and transport?

Autologous shipments — The timing and duration these shipments will vary based on patient location. Both the raw materials and the high value finished CGT therapy are irreplaceable. Ensuring that the courier arrives at the collection site with a best-in-class, pre-conditioned shipping container already on hand will save precious time.

Allogeneic shipments — These shipment times will also vary as they are generally distributed to multiple locations. Longer distances will require more time and possibly a “layover” to accommodate transport schedules. These shipments need a container with shipping delay protection.

#3 Are any special handling requirements required?

Failures at any step in this highly coordinated delivery process can have serious clinical consequences for the patient and significant financial consequences for the biopharmaceutical company. During your due diligence effort, this brief checklist can help ensure that you select a container with the necessary design capabilities:

- Are chain-of-custody checks required? The most reliable thermal shippers are those that have end-to-end tracking capabilities with real-time visibility into the shipment’s location and condition.

- Who will be packing the container at the collection site and at the CGT manufacturing site? Because this will rarely be the same person, a holistic packaging design is important. This is a foolproof design that uses intuitive engineering simple enough to ensure error-free use.

- Will the thermal shipper need to act as a temporary frozen storage unit for any duration along the route? Refrigerator or freezer capacity at interim points along the route is an important consideration in container selection. Your thermal shipper should have shipping delay protection to ensure the product remains in the required setpoint temperature range at all times.

- Does the container have adequate monitoring and tracking devices? The range of tracking devices that can fit inside the container are vast and can capture and convey real-time data related to temperature, shock and vibration, location, geofencing and more. Understanding where you need continuous visibility is essential for overall risk mitigation.

- Is open- and closed-lid tracking required? For high-value, temperature-sensitive CGT products, every time the shipping container lid is opened (and how long it stays open), creates risk for temperature excursions or potential theft. Securing thermal packaging with real-time tracking and alerts for lid opening and closing helps to eliminate these risks. Container suppliers who offer this type of tracking should also carry out thermal testing and risk modeling for various open-lid and delayed-transit scenarios to ensure optimal performance.

Cell and gene therapies: Managing COVID-19 disruptions, both upstream and downstream

The time-sensitive, temperature-sensitive supply chain for cell-and-gene therapies (CGT) requires a highly coordinated, highly choreographed dance under the best of circumstances. Against the backdrop of the global COVID-19 pandemic, 2020 is creating anything but the best of circumstances.

COVID-19 emerged quickly but now defines the landscape throughout the pharmaceutical industry and is creating unique challenges throughout the CGT arena. In particular, COVID-related issues are creating disruptions in three particular areas of the complex CGT manufacturing and care-delivery model:

- By creating health risks and obstacles for how patients and clinics are able to carry out their normal procedures and protocols. This makes it harder to reliably collect blood and stem cells from patients and third-party donors in the upstream clinical setting, and to administer the resulting manufactured CGT therapies to the immunocompromised patients who are eagerly awaiting them in the downstream portion of the process

- By creating delays, interruptions and other complications in transportation and delivery, throughout the tightly controlled cold chain that is utterly essential to safeguard and maintain the integrity of the biological source materials and lifesaving bioengineered CGTs at every step of the process

- By creating future competition (and inevitable bottlenecks) in the capacity and capabilities of the overall global cold chain, as all stakeholders in the cold chain prepare to meet the swift, global demand that will arrive soon, to deliver unprecedented volumes of COVID-19 vaccines (likely at cryogenic temperatures), once they are approved

Upstream challenges

The upstream process to both harvest blood and stem cells from patients, send those biological materials to dedicated biopharma facilities to create the custom CGT, and deliver them back to the clinical setting where the therapy will be infused into the patient relies on reliable, predictable, tightly integrated operations being carried out in hospitals, apheresis centers and other clinical settings. COVID-19 has created considerable risk and disruption to all clinical settings, undermining their ability to carry out normal activities as planned.

Whether the donor is the same patient who will ultimately receive the resulting CGT therapy at the same clinic (the autologous or “vein-to-vein” pathway), or is an approved third-party donor whose blood or tissue will be used to produce CGT therapies that will ultimately be administered to multiple patients in disparate locations (the allogeneic pathway), a variety of factors are upending regular operations in such clinical settings. These include:

- Increased concern on behalf of patients, in terms of whether travel to the clinical setting and time spent there may increase their risk of infection

- Reallocation of clinical space or practitioners’ attention to focus on COVID-19 patients

- Changing norms and requirements related to reduced scheduling and increased social distancing, travel restrictions and more

(Even further upstream, the clinical trials already underway to advance promising investigational CGTs are also being slowed down as trials have been suspended or postponed and trial enrollment has been challenged due to COVID-19. These disruptions will further delay potential commercial availability of these lifesaving therapies, but that is beyond the scope of this .)

Downstream challenges

The downstream processes in CGT (once the blood or tissue samples have been collected) require that painstaking efforts be undertaken to safeguard the temperature- and time-sensitive materials throughout their multi-step journey, as they move to the biopharmaceutical company’s centralized manufacturing site and ultimately back to the clinical setting for infusion into the patients. This highly coordinated cold-chain storage and transport process typically requires the time- and-temperature sensitive cargo to remain in transit for several days.

With countless flight delays and cancellations, and other pandemic-related disruptions, COVID-19 interruptions increase the risk of temperature excursions that would jeopardize the integrity of both the starting biological materials and the bioengineered therapies, creating extreme clinical and financial implications as these therapies are both vital and extremely extensive. As such, there is very little room for error here.

Moving from “white glove” to “smart shippers” can reinforce the CGT supply chain

Efforts to safeguard CGT shipments by relying on a “white glove” approach to chain-of-custody management have been a hallmark of the early years of the CGT industry. Such herculean efforts often rely on the use of dedicated human “couriers on board” who work to ensure the timely movement and door-to-door delivery of these high-value packages. Such efforts have, on occasion, required chartering.

Instead, stakeholders throughout the CGT arena should increase their reliance on technology-based solutions, which can help them to address delays that can arise as a result of COVID-19 and other challenges. Smart technology-based options include the use of sophisticated, long-duration packaging and shipping options that are able to maintain refrigerated and deep frozen temperatures using state-of-the-art insulation and other design advances.

Long-duration shippers also benefit from payload-condition sensors and integrated telemetry devices inside the packaging. Such smart devices provide tracking and notifications that allow stakeholders to monitor the condition of the shipment in real-time and intervene more quickly, if needed. The ability to keep a close eye on the location and condition of the package supports the strict overall chain-of-custody requirements that are so critical within the CGT arena.

Advanced shippers with state-of-the-art monitoring devices help CGT packages to avoid potential damage from travel and delivery delays by maintaining the biologic materials at the required refrigerated or deep frozen temperatures and helps to reduce the dependence on historic “white glove/courier-on-board” approach. Systems designed with these devices can provide real-time alerts for extended idle time, geofencing of routes, open alerts, shock and vibration alerts and more. Such advanced shipping containers and the data-driven insights they offer can help to maintain both precious CGT raw materials and high-value CGT finished products at the desired temperature for longer periods of time, allowing them to remain safe even in the face of travel and delivery delays.

Similarly, to safeguard the CGT cold chain in the face of COVID-19 (and other) delays, CGT producers should focus more heavily on contingency planning and strategic partnerships that enable rapid workaround solutions and fortify the supply chain allowing high-value cargo to weather the delays that can threaten to break links in the chain and still arrive intact and on time.

For example, when CGT stakeholders partner with larger carriers — such as those that have more redundant assets in place — these service providers are often able to quickly reroute shipments or in some cases the actual trucks, ships and planes as needed in the event of travel disruptions. This has the potential to give the cold chain “self-healing” attributes that can greatly reduce risk, safeguard the time- and temperature-sensitive cargo, and allow for more flexible and scalable solutions.

Closing thoughts

COVID-19 may be the first global pandemic to impact the nascent CGT industry, but it is not necessarily the last global event to strain the system. The lessons learned today, and the resulting upgrades in technology advances related to monitoring, data analytics, temperature-controlled packaging and more, along with more comprehensive strategic planning and modeling of “what if” scenarios and workaround solutions will create stronger, more resilient supply chains for these high-cost, lifesaving therapies. Implementing the upgrades. The need for improved real-time visibility and the importance of planning and partnerships that allow stakeholders to intervene quickly and effectively cannot be overstated. COVID-19 has underscored the need for all CGT stakeholders to invest in a paradigm shift that can both improve cold chain reliability and reduce risk.

Despite the impact of COVID-19, the maxim “It’s not a package, it’s a patient,” remains an absolute guiding principle throughout the CGT arena. At the end of the day, there is an actual immunocompromised patient waiting anxiously for the therapy to arrive safely, without incident, and with no temperature excursions that could compromise the integrity of the lifesaving therapy. Getting it right the first time is the only option, despite the added layer of unpredictability imposed by COVID-19.

COVID-19 Vaccine Distribution: Packaging an End to the Pandemic

It seems that about once every two or three weeks, my oldest child will ask me, “Dad, when will COVID be over?” It’s the question we all have, but the one no one can really answer. The hope is that a vaccine will go far in putting an end to the pandemic. Researchers and pharmaceutical companies have been working nearly around the clock since January to study and develop a vaccine and they are making extraordinary progress with more than 165 in development and 30 vaccines in human trials. But what about the next big question: How do we get a vaccine distributed to the world?

To the people stuck in their home offices in Milan, Seoul, Sao Paulo, Miami and Sydney, the answer to that question is simple: ship it! And wouldn’t it be wonderful if it was that easy? But those of us in the cold chain and pharmaceutical industries know that it’s far more complicated. And, COVID-19 has added a number of new obstacles to alter the complex, yet normal processes we’re used to, including less air cargo space, shipping delays and distribution to remote locations and that’s just the tip of the iceberg.

Overcoming these challenges will take considerable cooperation, creativity and flexibility from everyone in the cold chain industry. From our end – thermal shipping solutions – I have a few ideas on how we can help.

Addressing the Obstacles

REDUCED AIR CARGO CAPACITY / LONGER SHIPMENT DURATIONS

While normally not an obstacle, most of the COVID-19 vaccines currently in development will need to maintain a temperature of approximately -70°C (-94°F). Where this becomes a challenge is in longer shipment durations due to reduced air cargo capacity. Until passenger planes start flying again, this will not change because a large portion of air cargo is transported on the lower decks of wide body passenger jets. In order to manage a global distribution, freight forwarders will have to get creative with the resources available.

Let’s assume that forwarders will reserve most of the air cargo space for overseas shipments. Then what? The cargo gets moved to road or rail transport for distribution. Now instead of a transit time of 24-36 hours from manufacturer to local health agencies, we’re looking at potentially four to five days if there are no delays. This is where the thermal shipper becomes critical. It must be capable of maintaining the required temperature for a minimum of 120 hours in addition to meeting all of the government regulations and qualifications for temperature-controlled packaging. Do these containers exist? Yes. Thankfully, they do.

The passive parcel engineering and product teams here at CSafe recently revamped our entire line of thermal shippers with best-in-class vacuum insulated panel (VIP) technology. The entire line is pre-qualified to ISTA 7D and ISTA 3A worst case challenge testing and is available in 96+ hour and 120+ hour shipment durations. Though, I’ll mention that when we tested the 120 hour shipper against COVID-19 requirements, it far exceeded that duration. For the COVID-19 vaccine shipments, we’re recommending our -80°C solution (the line includes Controlled Room Temperature and +2°C to +8°C solutions as well) and manufacturers can choose from four sizes ranging from 5L to 35L with a 56L option coming soon.

EXTRA SAFETY PRECAUTIONS / NEW OR REMOTE LOCATION DISTRIBUTION

The next two issues we’re facing are all about time: shipping delays due to additional safety precautions and reaching new or remote locations. Either of these could result in even longer shipping durations. The easiest solution here is to add some insurance in the form of an active container. CSafe Parcel -80°C packaging shipped inside a CSafe RKN or RAP effectively controls the ambient temperature for the parcel boxes and extends the temperature protection to 10+ days. Add to this the track and trace technology that will be released in Q4 and that timeframe can be extended further with appropriate interventions.

REGULATORY APPROVALS

Regulatory approvals could come one at a time staggered by weeks or months or they could come in small or large groups. Global approvals may be staggered as well leading to even more complexity. It is impossible to predict how that will happen. Manufacturers are likely producing vaccines now in order to distribute doses immediately following approval. However, additional releases may come in waves with unpredictable timing due to raw material constraints or manufacturing issues.

We all know that raw materials for nearly any type of manufacturing takes some time to secure these days. CSafe is well prepared and we have yet to experience any disruption in our supply of raw materials. However, we’ve all learned that preparation and back-up plans are our friends. To that end, I would recommend that manufacturers place parcel orders for COVID-19 vaccine shippers when they begin production or shortly after and well before they send the vaccine for government approval. This should ensure that by the time the vaccine is approved, and the vials are ready to ship, your shippers and active containers will be on site and ready to load for transport.

SEASONAL FLU VACCINE

On the slim chance you’d forgotten, the northern hemisphere is about to enter flu season as well. According to the U.S. Centers for Disease Control (CDC), manufacturers have projected they will provide 194-198 million doses of flu vaccine – a considerable increase over last year’s production. What this means for COVID-19 vaccine distribution is that there is a competing vaccine for another deadly virus that will be shipping at a similar time frame further exacerbating the strain on cargo capacity and raw materials inventory.

Final Thoughts

No one can promise that this distribution effort will be completed without any major issues. There will be failures. Things will go wrong. The industry has never attempted anything close to this scale of distribution. There are 7.8 billion people in the world, and we have to give each of them the opportunity to get this vaccine. This is a herculean effort if I’ve ever seen one. What I do know and what I can promise, is that CSafe and our cold chain partners will do everything in our power to protect these vaccines while they are in our care. Our goal is “Temperature assured. Life enhanced.” and I can’t think of another opportunity that could represent that more so than this.

Achieving Irrefutable Chain of Custody for Cell & Gene Therapies with Smart Technologies

Chain of custody (COC) in the simplest of terms, details the location and time an item changed hands and who delivered and received the item. There are COC requirements for pharmaceuticals in every country to ensure patients receive genuine, viable medications. For cell and gene therapies, the COC must be flawlessly executed and requires even more data collection and documentation.

From the initial collection of raw material from the patient and administering the final treatment, the number of hand-offs and processes involved is vast and complex. As an example, last year, Thermo Fisher Scientific (TFS) published an article on the importance of COC documentation for biologics. It references all of the points of documentation required when shipping materials to a clinical site for patient administration:

- Shipper hand-off to courier

- Courier hand-off to TSA screener at departure airport

- Hand-off to TSA screener at arrival airport

- TSA screener hand-off to courier

- Courier hand-off to dosing center staff

- Hand-off to pharmacy staff who then documents the time, date and temperature of the therapy when placed in storage in the pharmacy

And that’s just a portion of the entire COC. All of these hand-offs present one large area of risk, but there are others.

PCI Clinical Services published a white paper not long ago where they identified five key risk factors relevant to the six primary stages of the cell and gene supply chain. It will come as no surprise to anyone that temperature excursions ranked as high risk at both ends of the supply chain and time excursions were labeled high risk for starting material and medium risk for therapy delivery in the example they used. I would stipulate that, more often than not, time excursions would also be high risk at both ends.

Given that the risks we’re discussing could prove fatal to a patient, COC is absolutely crucial and must be completed without error. This is where smart technology can help improve the commercialization process for these therapies by automatically collecting data throughout the shipment process in each direction and providing alerts about any temperature or time excursions and protect against mishandling.

A real-time tracking device integrated into the packaging along with cooperation from various partners in your supply chain will allow cell and gene therapy manufacturers to have visibility into:

- Shipment departures and arrivals using facility location geofence

- GPS location while on the ground providing details on speed of transport and any idle time

- Temperature alerts that allow quick reaction to prevent excursions

- Impact/shock events

For the cell and gene therapy industry, this real-time visibility allows for COC confirmation as well as the ability to intervene in the event of an excursion. It also supports patient identity tracking throughout the shipment. Along with considerable benefits for COC, a smart tracking device can collect considerable data during the shipment process that will provide proof of increased industry and regulatory compliance and GDP requirements.

Chain of custody is important for every shipment, but the implications for a broken COC in the cell and gene supply chain can be the difference between life and death for a patient. By integrating smart technology throughout the supply chain you can protect your COC, your product, and your patient.

The True Cost of a Cell & Gene Payload

As the cell and gene industry continues to grow manufacturers must determine where it is – and is not – acceptable to take cost savings measures to improve the affordability of these treatments.

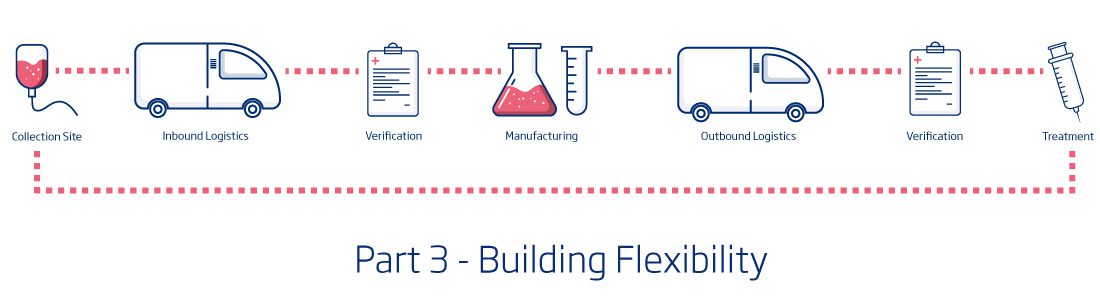

Continue ReadingSafeguarding the Cell & Gene Supply Chain – Building Flexibility

Emilio Frattaruolo, CPP, Vice President of Innovation, Passive Systems discusses how to build flexibility into the cell and gene therapy supply chain.

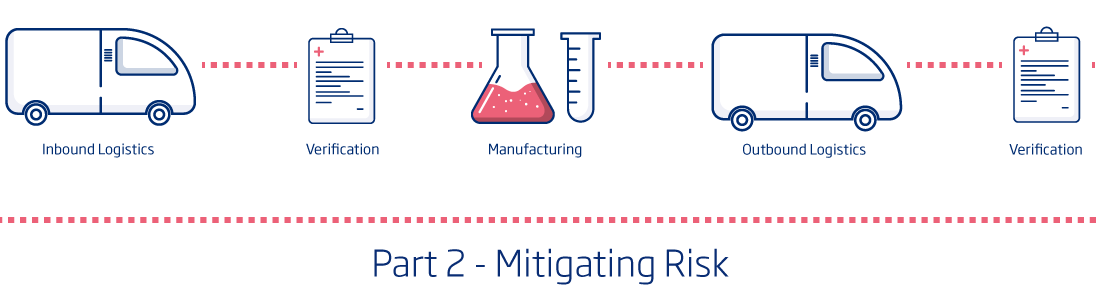

Continue ReadingSafeguarding the Cell & Gene Supply Chain – Part 2

Emilio Frattaruolo, CPP, Vice President of Innovation, Passive Systems discusses how to mitigate risk in the cell and gene therapy supply chain.

Continue ReadingSafeguarding the Cell & Gene Supply Chain – Part 1

Emilio Frattaruolo, CPP, Vice President of Innovation, Passive Systems discusses how to manage compliance in the cell and gene therapy supply chain.

Continue Reading